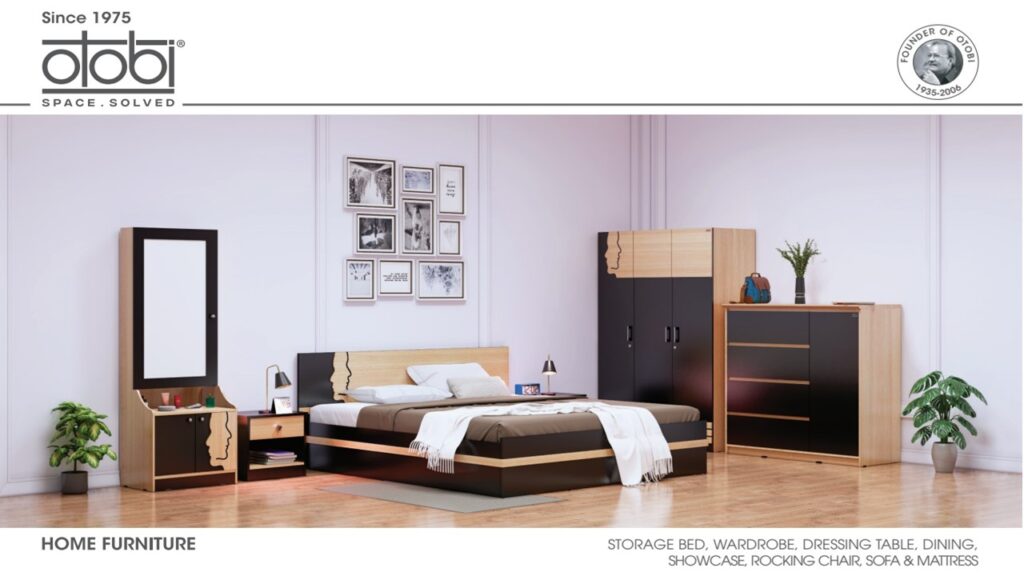

Otobi Limited is a prominent furniture manufacturer. They embarked on its journey with the aspiration to redefine comfort and style in 1975 under the visionary leadership of the late Chairman Nitun Kundu. Originally known as Otobi, the company’s primary focus has always been on creating exceptional furniture that combines aesthetics with functionality. Otobi has become a household name in Bangladesh, and its commitment to delivering top-notch quality is at the core of its operations.

How Otobi Furniture Guarantees Product Quality

Otobi’s dedication to ensuring the highest product quality standards is unwavering. It all begins with the selection of top-quality materials and follows a meticulous production process.

Raw Materials and Sustainable Practices

The foundation of Otobi’s commitment to quality starts with the careful selection of raw materials. The company uses a range of materials, including high-quality wood, particle boards, plywood, and metal in its furniture manufacturing.

Otobi is committed to sustainable practices, and it sources wood from environmentally responsible suppliers who adhere to strict sustainability standards.

Otobi’s adherence to sustainability is further underscored by its participation in and promotion of sustainable forestry practices. The company has its own wood seasoning plant, which plays a vital role in reducing moisture content in wood efficiently and environmentally consciously.

This expedited seasoning process, taking only 14 to 21 days, significantly reduces the traditional sun-drying duration.

Moreover, Otobi places great emphasis on reducing waste and maximizing efficiency. Their production processes involve recycling and repurposing materials to minimize environmental impact.

Read Also: Top 10 Furniture Exporters of Bangladesh

Precise Manufacturing and Quality Control

The manufacturing process at Otobi is a model of precision. Every piece of furniture undergoes meticulous design and quality control checks at various stages of production. Automated machinery and cutting-edge technology are employed to ensure that each product meets the highest standards of accuracy and quality.

The production process is divided into distinct stages based on the type of product. Each product category follows a tailored production line to guarantee that the design, dimensions, and quality are consistent.

Additionally, Otobi manufactures its own foam, using different types to achieve optimal comfort. The company produces mattresses that provide superior user comfort through a combination of rebonded foam and felt. The upholstery department, responsible for crafting chairs and sofas, carefully selects and cuts imported fabrics using advanced machinery for precise dimensions.

In the case of metal furniture, Otobi maintains dedicated production lines for different metal types. They utilize modern machinery for precise cutting and punching, coupled with a four-stage quality control process to ensure that metal furniture adheres to the highest standards.

Stringent Quality Checks and Continuous Improvement

Otobi’s dedication to quality is evident through its stringent quality control process. The company conducts a four-tiered quality inspection regimen that significantly reduces the chances of defects in its products. Various departments employ quality control tools, including flow charts and check sheets, for operational convenience.

Furthermore, Otobi employs the “Cause and Effect” diagram, also known as the “Ishikawa” diagram, to address quality control-related issues. This approach allows for thorough root cause analysis and enables the company to continually refine its processes through the principles of Kaizen, ultimately preventing the recurrence of similar errors.

Otobi’s commitment to product quality extends to the final stages of production, where each piece of furniture undergoes meticulous coloring and varnishing processes. The type of furniture determines the specific coloring method, ensuring that each piece is treated in the most suitable way. These processes involve advanced techniques that reduce waste and enhance precision.

Conclusion

Otobi’s journey to ensuring the highest quality of furniture is driven by a steadfast commitment to its customers. By adhering to sustainable practices, utilizing top-quality materials, and maintaining rigorous quality control standards, Otobi consistently delivers furniture that combines elegance with durability.

Every piece of furniture produced by Otobi undergoes multiple checks to guarantee that it meets the highest standards of quality. These practices underscore Otobi’s dedication to delivering exceptional products to its valued customers.

Ref: OTOBI Furniture Care Information